WINDOW EFFICIENCY AND PERFORMANCE

WINDOW U-VALUE AND WINDOW AVAILABILITY:

THE TRADE-OFFS

To make informed window and door purchase decisions, particularly regarding energy savings, owners and code officials must understand the real-world implications limiting choices for consumers as the u-value requirements are lowered.

In Colorado’s Front Range communities, we are unable to avail ourselves of all of the technological advantages that the window and door industry has deployed to improve energy efficiency. There are historical and geographical reasons for this limitation that, when combined, limit the window and door industry’s interest in targeting innovative solutions for our market.

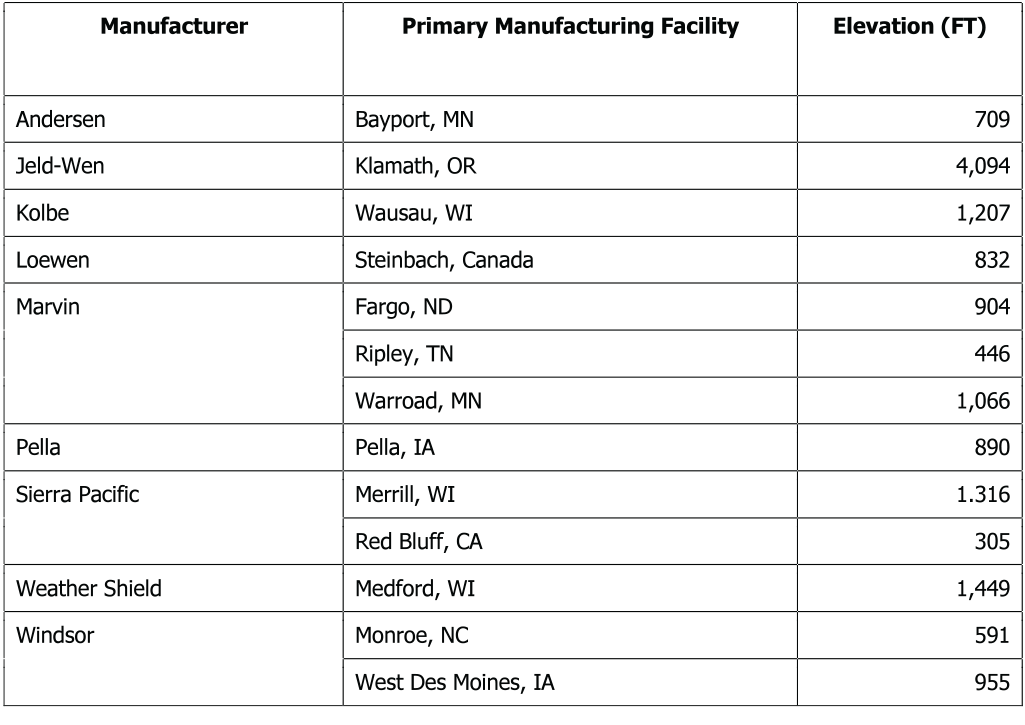

Most wood and clad-wood windows are manufactured at an elevation of 1,000 feet or less (see Table A below). The historical reason for this relates to the source lumber for manufacturing. This will become important when we discuss the benefits and limitations of inert gas-filled insulated glazing units (“IGU” or “IGUs”) in improving window u-value performance.

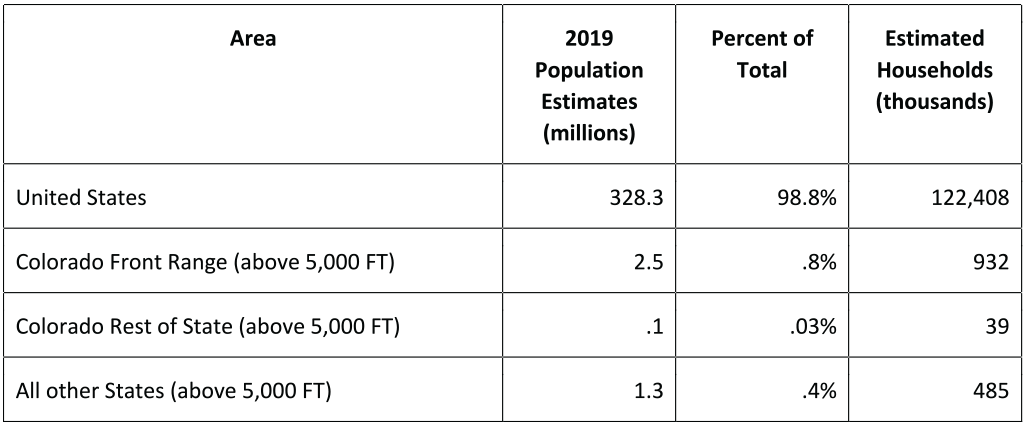

Also driving the limitation on the use of inert gas-filled IGUs, the most popular method for increasing efficiency, is the elevation where windows and doors are to be installed. Only 1.2% of the U.S. population lives at an elevation at or above 5,000 ft, 2/3s of which are in Colorado’s Front Range communities (see Table B). Glass manufacturers do not have an economically viable interest in developing ways to work around altitude issues for such a small segment of the U.S. market.

U-Value Performance

Here is how the difference in elevation at the point of manufacture and at the job site limits the use of inert gasses such as argon to improve window u-value performance: When IGUs are installed at altitudes above where they are manufactured, they will bow outward, creating stress in the glass and IG edge seal. Depending on unit size, airspace glass thickness, and tempering, this stress can be enough to cause glass breakage and unit failure. The shorter a leg, width, or height, the greater the risk. The conventional approach to alleviating these problems is to install a capillary tube. The tube permits the IGU to pressure-equalize with the local atmosphere but prohibits using inert gas-filled IGUs. For window and door companies that have their IGUs manufactured by Cardinal Corp, as opposed to creating the IGUs in-house, Cardinal provides charts that help window and door salespeople know which units can use argon-filled IGU while maintaining the 20-year non-prorated warranty and a known seal failure rate of 2 out of 1,000 over 20 years. As argon-filled IGUs are Marvin’s standard offering, we specify argon when the altitude charts permit.

Beyond argon, two additional tools are available to address u-value performance in the Colorado market. Triple-pane glazing has long been available to improve u-values. However, with the elevation issues, the bowing of the lites in a triple-pane unit as it reaches the job site elevation risks the panes coming in contact with one another and scratching the Low-E coating typically found on surface two and four, with surface one being the outside of the exterior pane and surface six being the glass you can touch will inside the house. Therefore, Colorado window and door dealers are unable to use argon-filled tri-pane IGUs, limiting the available benefit while increasing cost and weight.

There are companies, such as Alpen High Performance Products, based in Louisville, Colorado, experimenting with tri-pane units, with the middle piece of glass being a thin element like the glass on your smartphone. The two primary glass and IGU providers in North America, Cardinal Corp, and Guardian Glass, have not yet announced plans to introduce similar products

Alternatively, both glass companies have introduced room side (surface 4 in dual pane units and surface 6 in tri-pane units) low-emissivity (low-e) coatings which, when added to traditional surface 2 (surface 4 in tri-pane units) low-e coatings, improves glass u-value performance by rejecting heat back to its interior source. With the addition of the room side Low-E coating, the room side pane of glass will be colder than the same glass construction that does not include the room side coating. This will result in a slightly colder room side pane in winter conditions with the potential of having a higher probability of room side glass condensation in the winter. This is very dependent on the outdoor ambient temperature, indoor room temperature, and the % relative humidity in the room.

What does this all add up to?

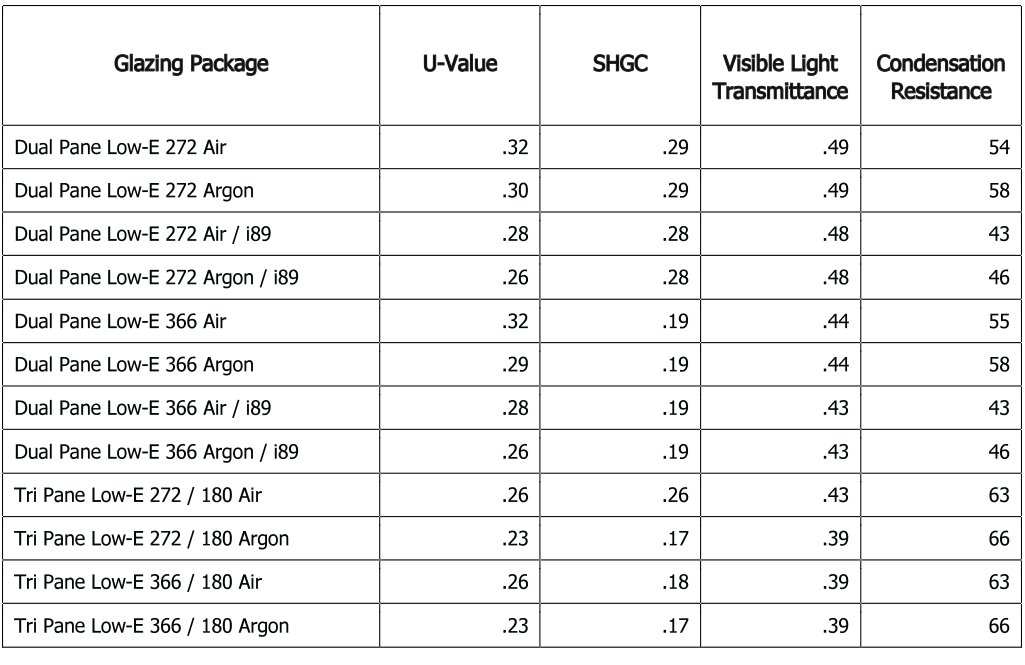

Today’s residential designs are calling for larger and larger units. To illustrate the performance levels and trade-offs discussed here, let’s compare the performance values of various configurations of glazing in a 40” x 64” casement window:

You will see that the best u-value bang for buck is the dual-pane, argon-filled unit with a room-side i-89 Low-E coating. However, that only provides a u—value of .26. Comparing the .26 u-value plateau against the .23 capabilities customers in lower elevations can enjoy illustrates the performance/choice dilemma in the Colorado Front Range market.

Table A: Prominent Window and Door Manufacturers

Table B: Population Dispersion by Elevation

Appendix: Definitions

Source: Cardinal Corp Technical Glass Guide v3.0©

Condensation Resistance (CR): measures how well a window resists the formation of condensation on the inside surface. CR is expressed as a number between 1and 100. The rating value is based on interior surface temperatures at 30%, 50% and 70% indoor relative humidity for a given outside air temperature of 0 ° Fahrenheit under 15 mph wind conditions. The higher the number, the better a product is able to resist condensation. CR is meant to compare products and their potential for condensation formation.

U-Factor: The heat flow rate through a given construction, expressed in BTU/hr./ft2/°F (W/m2/°C). The lower the U-Factor, the less heat is transmitted through the glazing material. Winter nighttime U-Factors are calculated for outside air temperature at 0 °F (-18 °C), outside air velocity at 12.3 mph (5.5 m/s) and a solar intensity of 0 BTU/hr./ft2 (0 W/m2). Unless otherwise noted, all U-factors provided use winter nighttime conditions.

R-Value: The thermal resistance of a glazing system expressed in hr•ft2•ºF/BTU. R-Value is the reciprocal of U-Factor, R=1/U. The higher the R-Value, the less heat is transmitted through the glazing material.

Solar Heat Gain Coefficient (SHGC): The fraction of incident solar radiation that enters a building as heat.

It is based on the sum of the solar energy transmittance, plus the inwardly flowing fraction of absorbed solar energy on all lites of the glazing. Dimensionless and varying between 0 and 1, the smaller the number, the better the glazing is at preventing solar gain.

Ultraviolet Light: In a portion of the solar spectrum (300 to 380 nm), the energy that accounts for the majority of fading of materials and furnishings.

Visible Indoor Reflectance: The percentage of visible light that is reflected from the glass surface(s) to the

inside of the building. It is better to have a low visible indoor reflectance to enhance visibility when viewing objects outdoors in overcast or nighttime sky

conditions.

Visible Light Transmittance: In the visible spectrum (380 to 780 nm), the percentage of light that is transmitted through the glass relative to the CIE Standard Observer.

Posted June 14, 2022 by Signature Windows + Doors